Filter Press Plate and Frame vs Recessed Filter Press

Filter Press Plate and Frame vs Recessed Filter Press

Blog Article

Understanding Both Designs

Filtration systems rely on two major types: the plate and frame filter press and the recessed filter press. Each offers distinct features, and choosing the right one depends on your application and desired results.

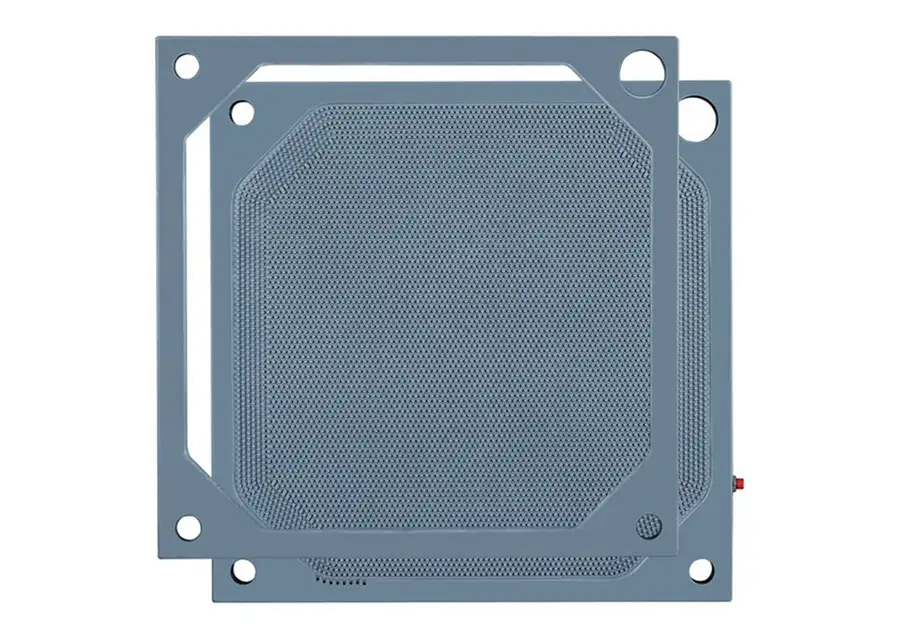

What Is a Plate and Frame Filter?

The Plate And Frame Filter Plate design uses alternating plates and frames. The frame holds the slurry, while the plate supports the filter cloth. This setup allows efficient solid-liquid separation and higher filtration precision. Operators can easily inspect and clean each section.

Recessed Filter Press Structure

In contrast, the recessed press uses plates with a built-in cavity. These plates form chambers when pressed together. Slurry enters the chamber, solids stay behind, and liquid exits through cloths. This design is compact and often easier to automate.

Key Differences to Consider

The Plate And Frame Filter Plate is ideal for small batches or precise filtration tasks. It allows quick access for cleaning. However, it may take more time to set up. The recessed system suits continuous, large-scale operations. It's faster but less flexible in terms of inspection and cloth changes.

Which One to Choose?

If your goal is flexible maintenance and detailed control, go with the Plate And Frame Filter Plate. If speed and volume matter more, a recessed press works better. Both types play critical roles in industries like mining, food processing, and wastewater treatment.

Report this page